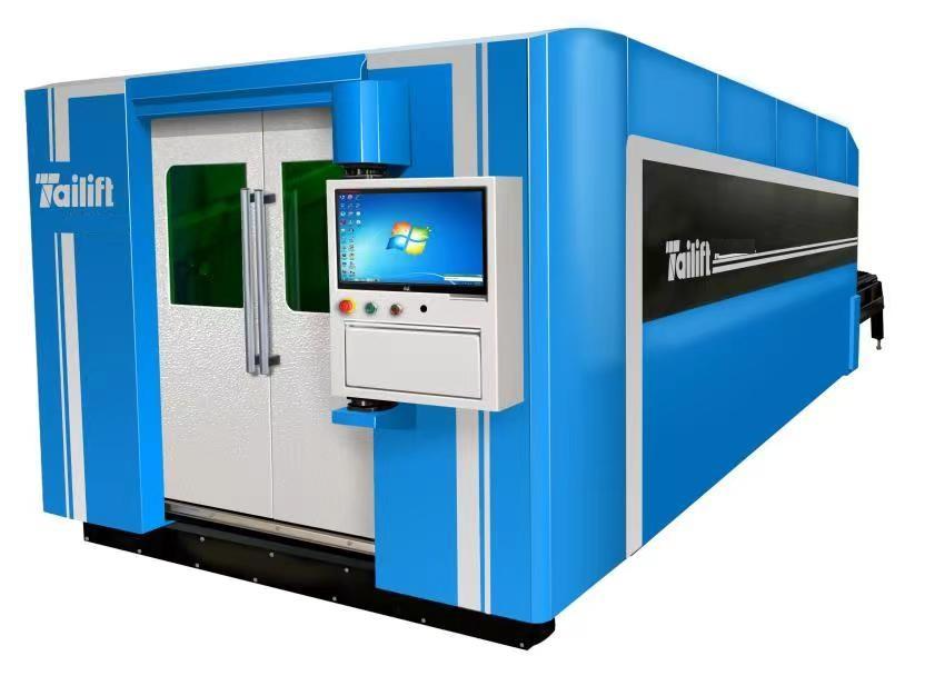

Fiber Laser Cutting Machine

User friendly

Fast cutting speed, low operating cost and fast return on investment.

Auto Edge finding. Effectively used in big sheets.

The electric energy conversion heat energy conversion rate is high, and an effective power saving effect is achieved.

Low Maintenance. without adjustments of light path and reflect lens, no service requirements.

Closed Frame Base with Gantry Type (Dual-Drive) Integrated Servo Control System to Increase Working Speed and Efficiency.

Double Working Table Saves Loading/Unloading Time and Increase Productivity.

Full Covered Machine Body with OD6+ Fiber Protection Safety Glass Window Ensure the Operator Safety and Effectively controls the Laser Radiation in the Environments, Good Light Probation.

User friendly

Fast cutting speed, low operating cost and fast return on investment.

Auto Edge finding. Effectively used in big sheets.

The electric energy conversion heat energy conversion rate is high, and an effective power saving effect is achieved.

Low Maintenance. without adjustments of light path and reflect lens, no service requirements.

Closed Frame Base with Gantry Type (Dual-Drive) Integrated Servo Control System to Increase Working Speed and Efficiency.

Double Working Table Saves Loading/Unloading Time and Increase Productivity.

Full Covered Machine Body with OD6+ Fiber Protection Safety Glass Window Ensure the Operator Safety and Effectively controls the Laser Radiation in the Environments, Good Light Probation.

Model :

TL Series (Tailift)

Tailift Equipment with the latest generation Cypcut + Advantech LASER source vibration device, to provide the most cost-effective processing tool.

Using gantry-type bilateral drive, with integrated servo control system, faster, more efficient cutting.

Dual exchange table, can accelerate the different size materials, reduce material handling time.

Medium thickness sheet stability while cutting at high speed.

Full-splash guard with OD6 + grade fiber optic protective glasses, effectively block the laser radiation.

Full format lighting helps for good observation.

Movement method: 3 axes simultaneously controlled

Control method: Cypcut + Advantech controller

Laser head: Automatic

Table type: Pallet changer